Imagine being able to access real-time data and the exact status of any product or system—whether it’s a production machine, transportation infrastructure, or even your own body. Sounds futuristic? With the digital twin, this is already a reality. A digital twin not only provides a precise digital representation of a physical object but also revolutionizes the way we use data and make decisions.

In a connected world where efficiency, precision, and sustainability matter, the digital twin is becoming an indispensable tool for businesses. But what exactly is behind it? How is a digital twin created and used? What challenges and opportunities does it bring? And most importantly: how can you benefit from this technology?

This article offers you a comprehensive introduction to the topic, highlighting practical applications and technical insights. You will learn how digital twins are used across different industries, what technological innovations they support, and the economic benefits they provide. From integration with digital product passports to supply chain optimization and predictive maintenance—the possibilities are nearly limitless.

Read on to discover how the digital twin is driving Industry 4.0 and why investing in this groundbreaking technology is worthwhile. Learn how implementing digital twins can not only boost your efficiency but also secure long-term competitive advantages.

Integration of Digital Twins and Digital Product Passports

The combination of digital twins and digital product passports offers significant advantages. A digital twin is a virtual representation of a physical product, process, or system that continuously collects and analyzes data. The digital product passport contains detailed information about a product, such as origin, materials, manufacturing processes, and recycling options.

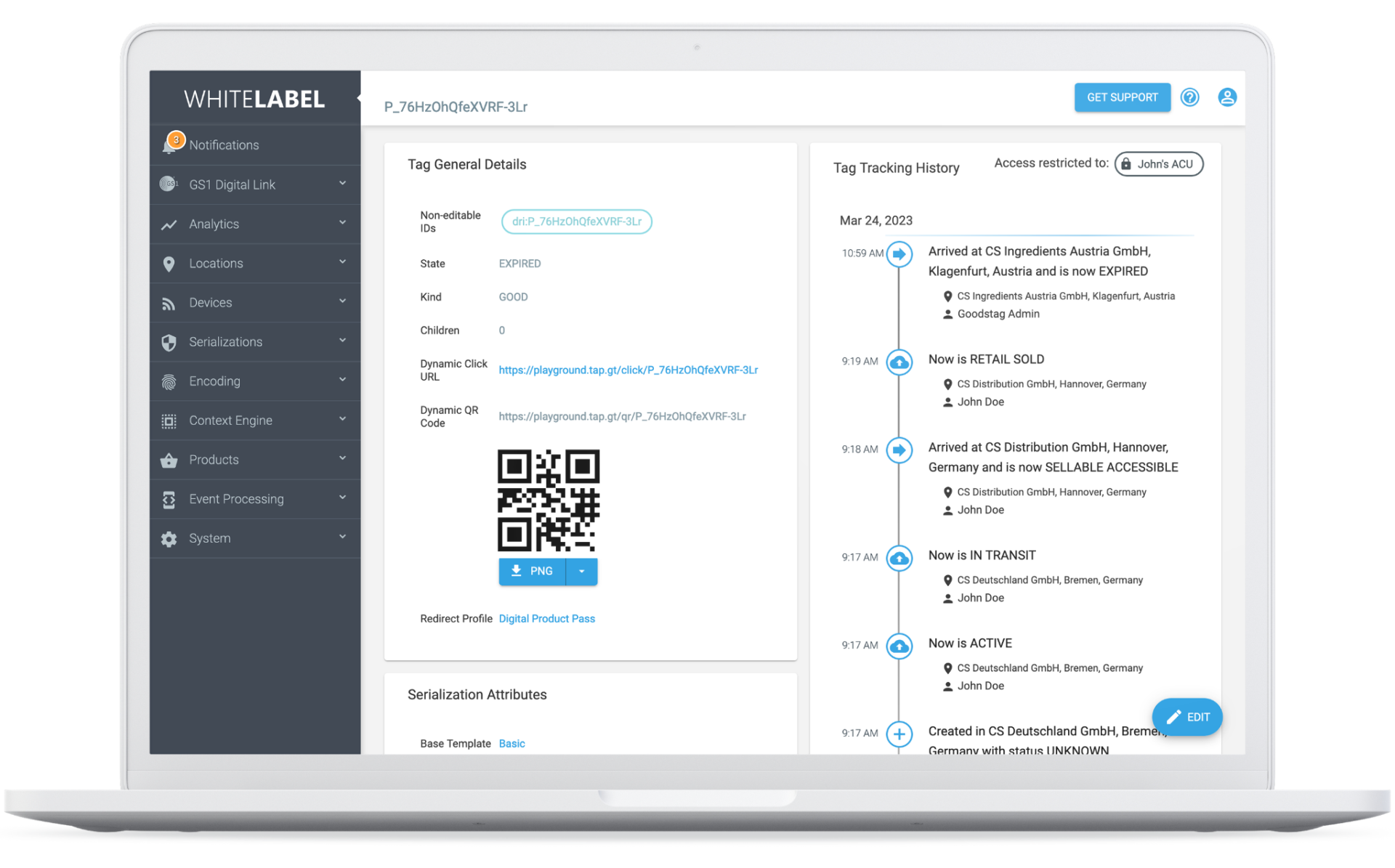

This integration ensures complete transparency and traceability. A digital twin documents the entire lifecycle of a product in real-time, while the product passport provides all relevant information in a structured manner. Changes in the digital twin are immediately updated in the product passport, increasing the reliability of the data. Learn more about our solutions.

Decentralized technologies such as blockchain ensure tamper-proof and transparent data storage, enhancing IT security. Companies like Circularise already use blockchain-based product passport software that seamlessly integrates into ERP systems like SAP and is utilized by leading firms such as Porsche and Philips.

Technical Fundamentals and Implementation

The implementation of a digital twin requires a robust IT infrastructure and the integration of various technologies such as IoT, Artificial Intelligence (AI), and Big Data analytics. These technologies enable the collection and analysis of real-time data to continuously monitor the condition and performance of a product or system.

Data Collection and Integration

The first step in creating a digital twin is the reliable collection of data. Sensors measure physical parameters such as temperature, pressure, and vibration in real-time. Seamless integration of these sensors ensures that the digital twin always reflects current and accurate data. Contact us for a personalized consultation.

Data Processing and Storage

Once collected, the data must be processed and securely stored. Blockchain technology provides the necessary data integrity through decentralized storage and cryptographic security. This prevents manipulation and ensures the reliability of the data.

Data Analysis and Simulation

Using advanced algorithms and machine learning, the data is analyzed to identify patterns and make predictions. These analyses enable precise simulations of the physical object, allowing informed decisions to be made based on real-time information.

Interoperability and System Integration

For successful implementation, the digital twin must be seamlessly integrated into existing IT and ERP systems. Standardized data interfaces and protocols facilitate this integration and ensure that all relevant stakeholders have access to the latest data.

Application Scenarios and Benefits

Digital twins offer a wide range of applications and benefits:

Manufacturing Industry

In manufacturing, digital twins monitor production processes in real-time, detect errors early, and optimize operations. This minimizes downtime and increases operational efficiency.

Construction

In the construction sector, digital twins enable predictive maintenance of buildings and infrastructure. Potential issues are identified and resolved early, extending the lifespan of structures and reducing maintenance costs.

Healthcare

In healthcare, digital twins of patients can be created to develop personalized treatment plans and monitor the effectiveness of therapies in real-time. This leads to more individualized and efficient medical care processes.

Logistics and Supply Chains

Digital twins enable the digital replication of production and logistics processes, allowing for better planning and control of the supply chain. Bottlenecks and inefficiencies can be identified and addressed early, improving overall supply chain performance.

Digital Product Passport

In the context of the digital product passport, digital twins ensure seamless documentation and tracking of a product’s entire lifecycle. Real-time updates enhance the transparency and reliability of product information.

The benefits include higher data security, continuous improvement through real-time analytics, more efficient resource utilization, and significant cost savings. Get advice from our experts.

Economic Aspects and ROI

The economic benefits of digital twins are evident in the reduction of operational costs, improvement of product quality, and increase in operational efficiency. By detecting problems early and optimizing maintenance processes, companies can minimize downtime and extend the lifespan of their products.

Reduction of Operational Costs

Precise monitoring and control of processes prevent unnecessary expenses and enable more efficient resource utilization. This leads to significant savings in production and maintenance.

Improvement of Product Quality

Digital twins allow for detailed analysis and optimization of products throughout their lifecycle. This improves product quality and reliability, increases customer satisfaction, and strengthens customer loyalty.

Increase in Operational Efficiency

Automated data collection and analysis enable faster and more precise process control. This enhances productivity and optimizes the utilization of available resources.

The return on investment (ROI) of digital twins is substantial, especially when combined with digital product passports. Companies that implement these technologies early secure a competitive advantage and achieve long-term success in the market.

Challenges and Solutions

Despite the numerous advantages, there are challenges in implementing digital twins:

Integration and Interoperability

Connecting different systems and databases is often hindered by proprietary systems and incompatible interfaces. Standardized interfaces and collaboration with technology providers are key solutions.

Data Security and Privacy

Digital twins process large amounts of data that must be protected from unauthorized access. Technologies such as blockchain offer decentralized and tamper-proof storage solutions that enhance data security.

Acceptance and Willingness for Digitalization

Lack of knowledge and trust in new technologies can delay adoption. Training and information campaigns that highlight benefits and applications are crucial to overcoming this hurdle.

Economic Viability and ROI

Initial investments in technology and infrastructure must be weighed against long-term savings. Pilot projects and best-practice examples can demonstrate economic benefits and increase acceptance.

Solutions

A holistic approach that combines technological innovation, organizational changes, and economic considerations is essential. The use of modern technologies, staff training, and collaboration with specialized providers are crucial to fully leveraging the benefits of digital twins.

Conclusion

The digital twin offers a transformative opportunity to enhance efficiency and transparency across various industries. By seamlessly integrating into existing systems and utilizing cutting-edge technologies such as blockchain, you can optimize your processes and ensure that all relevant data is always available and immutable. This is particularly critical in the context of digital product passports to guarantee product traceability and authenticity.

GoodsTag supports you in leveraging these innovative technologies profitably. Our expertise in implementing digital twins and our comprehensive range of services, including the heat pump check, ensure that you receive the best possible solutions tailored to your needs. Contact us now to get more information and discuss your specific requirements. Our team is ready to help you fully capitalize on the benefits of digital transformation.